Introduction

In recent years, the manufacturing industry has witnessed a significant transformation, largely driven by advancements in technology. One of the most exciting developments in this space is the launch of AI-powered digital twin tools by Amazon Web Services (AWS). These innovative tools are set to revolutionize the way manufacturers operate in the United States, providing new opportunities for efficiency, productivity, and cost reduction.

What are Digital Twins?

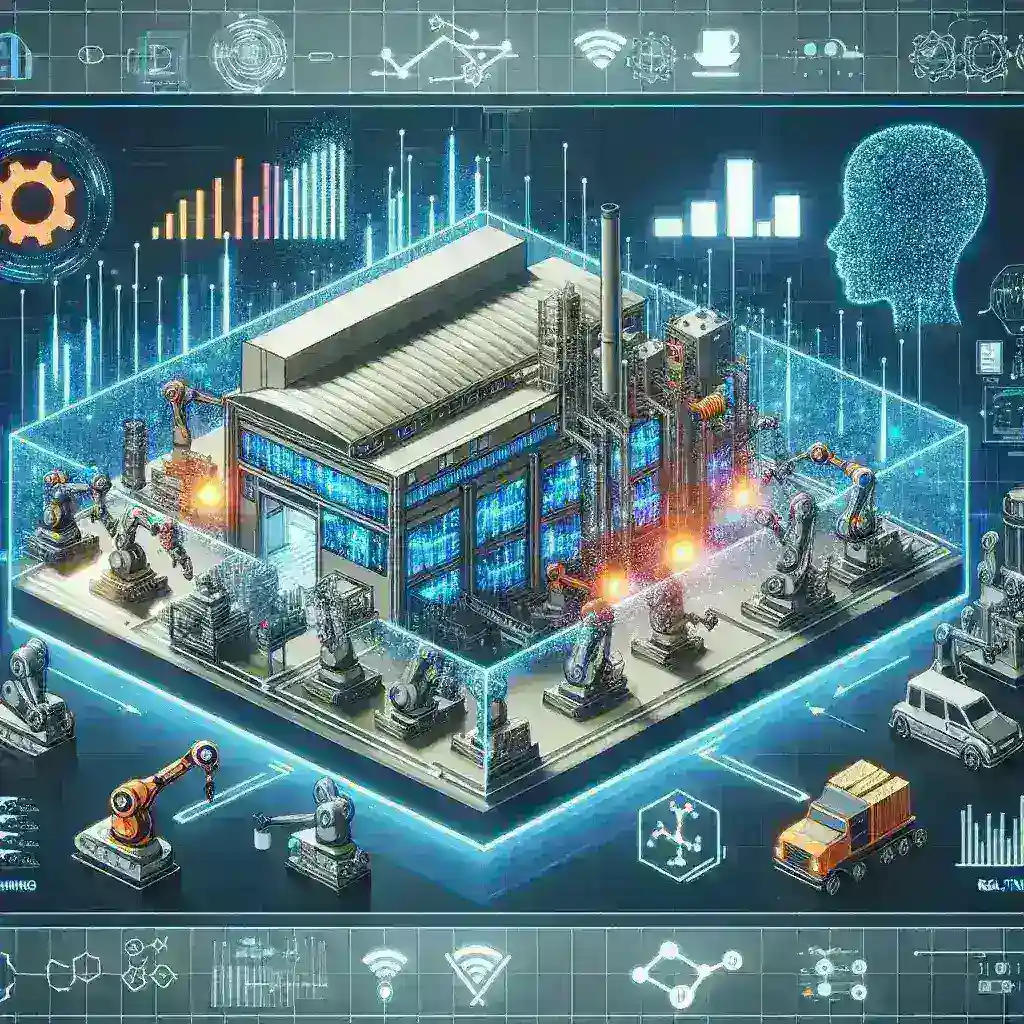

To understand the impact of AWS’s new tools, it is essential to first grasp what digital twins are. A digital twin is a virtual representation of a physical object or system, created using real-time data. This digital replica allows manufacturers to simulate, analyze, and optimize their operations without disrupting the physical systems. By integrating AI technologies, these digital twins can learn from historical data and predict future outcomes, enabling proactive decision-making.

The Role of AI in Digital Twins

Artificial Intelligence plays a crucial role in enhancing the functionality of digital twins. By utilizing machine learning algorithms, manufacturers can analyze vast amounts of data collected from sensors and IoT devices. This analysis provides insights into system performance, identifies potential issues, and suggests optimal solutions. The result is a more agile and responsive manufacturing process that can adapt to changing conditions.

AWS’s Innovative Approach

Amazon Web Services has a history of providing cutting-edge technology solutions, and its new AI-powered digital twin tools are no exception. By leveraging AWS’s cloud infrastructure, manufacturers can access robust computing power and storage capabilities, allowing them to create and manage digital twins at scale. This initiative aligns with AWS’s commitment to driving digital transformation across various industries.

Key Features of AWS Digital Twin Tools

- Scalability: AWS’s tools can cater to the needs of small manufacturers as well as large enterprises, adapting to varying data volumes and complexity.

- Integration: The tools seamlessly integrate with existing manufacturing systems and IoT devices, ensuring a smooth transition to digital twin technology.

- Real-Time Analytics: With continuous data streaming, manufacturers can monitor their operations in real time, allowing for immediate adjustments and improvements.

- Predictive Maintenance: The AI algorithms can predict equipment failures before they occur, minimizing downtime and maintenance costs.

- Enhanced Collaboration: Teams can collaborate more effectively by sharing insights derived from digital twins, leading to faster decision-making.

Benefits of AI-Powered Digital Twin Tools

The introduction of AWS’s AI-powered digital twin tools brings several advantages to U.S. manufacturers:

1. Improved Efficiency

AI-driven insights allow manufacturers to optimize their processes, reducing waste and increasing operational efficiency. By simulating different scenarios, companies can identify bottlenecks and implement strategies to address them.

2. Cost Reduction

With predictive maintenance capabilities, manufacturers can significantly cut down on unplanned downtime and repair costs. This proactive approach leads to better resource allocation and improved profitability.

3. Enhanced Product Quality

By continuously monitoring and analyzing production processes, manufacturers can ensure that their products meet quality standards. Digital twins can help in identifying defects early in the production cycle, allowing for timely interventions.

4. Increased Innovation

Digital twins enable manufacturers to experiment with new designs and processes in a virtual environment without the risks associated with physical trials. This fosters a culture of innovation and experimentation.

Real-World Applications

AWS’s AI-powered digital twin tools are already making waves in various sectors of U.S. manufacturing:

Automotive Industry

Automakers are using digital twins to optimize their production lines, improving assembly efficiency and reducing the time to market for new vehicle models. By simulating different assembly configurations, manufacturers can identify the most effective setups.

Aerospace

The aerospace sector benefits from digital twins by enhancing the maintenance and operation of aircraft. Airlines can monitor the performance of individual aircraft in real time, predicting maintenance needs and minimizing operational disruptions.

Consumer Goods

Companies in the consumer goods sector leverage digital twins to streamline their supply chains. By analyzing data from suppliers, manufacturers can better manage inventory levels and respond to changing consumer demands.

Challenges and Considerations

While the benefits of AWS’s digital twin tools are substantial, manufacturers must also consider potential challenges:

1. Data Security

As with any cloud-based solution, data security is a paramount concern. Manufacturers must ensure that their sensitive operational data is protected from cyber threats.

2. Initial Investment

Implementing digital twin technology requires an upfront investment in infrastructure and training. Manufacturers must weigh the costs against the long-term benefits.

3. Change Management

Transitioning to digital twins may require a cultural shift within organizations. Employees will need training and support to adapt to new processes and technologies.

Future Predictions

The future of manufacturing is undoubtedly intertwined with the evolution of digital twin technology. As AI continues to advance, we can expect even more sophisticated digital twins capable of simulating complex behaviors and scenarios. This will empower manufacturers to push the boundaries of innovation, creating smarter, more adaptable production processes.

Conclusion

Amazon Web Services’ launch of AI-powered digital twin tools marks a significant milestone for U.S. manufacturing. By embracing this technology, manufacturers can enhance efficiency, reduce costs, and foster innovation in an ever-evolving marketplace. As the industry continues to adapt to new technologies, the integration of digital twins will play a crucial role in shaping the future of manufacturing.

For manufacturers looking to stay competitive, investing in AWS’s digital twin tools could be a pivotal step towards achieving operational excellence and driving sustainable growth.

Leave a Reply